The Little Drifter That Will.

Posted: Tue Jul 16, 2013 9:12 pm

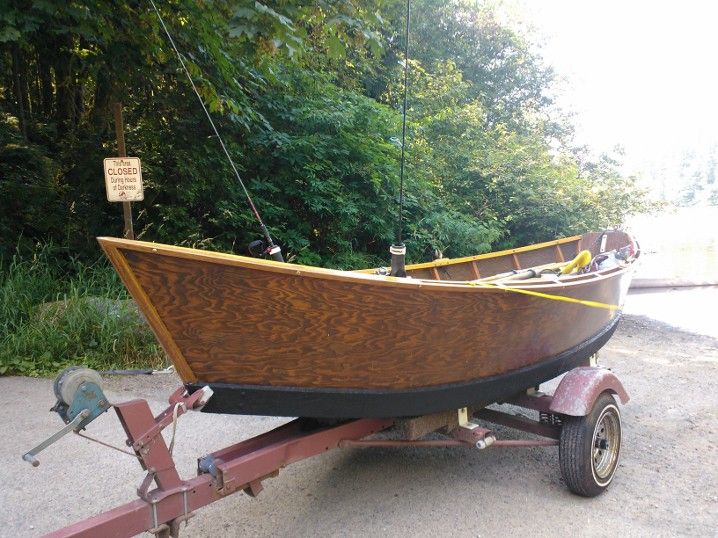

Ok so a couple of us die hard Power boat guys decided we need a boat for the little lakes with no motors and to go where no jet sled dare...... OK I'm getting into swinging a fly more and more these days too but, mainly because of local interference, truck and trailer damage and bullet holes...... So the Sickbayer and I got drunk, smoked cigars and all manner of mayhem that proceeded, we decided we must have a wood boat. We were looking for a Don Hull with the wide stern but got aced on a couple and found this. It was a must have from our first sight. She was built from plans that were drawn form a guy in Ferndale, his name escapes me now but he was a very prolific designer in the 60's and 70's. She was built in the late 70's buy the previous owner who was a cabinet maker/carpenter by trade.

On the way home from Tumwater, stopped Cabelas and the License store and transferred the title on the trailer.

At Home in the Drive.

We knew there was going to be some repair to the bottom as the glass had been broached in a couple location. We got her off the trailer and turned her over on to the saw horses....Note to self, when turning over a drift boat have as many people as possible. Sickbayer and I just about busted a nut on the flip but we made it. After we got her turned we looked at the little spots and found the glass had let go of the wood on the entire bottom. and we were able to pull it off in a couple of pieces. At this point we found the boat had been built with a double bottom, so it has two sheets of three eighths in the center danger zone with glass in between.

Bottom Ripped Off and Ready to Go.

And the sanding and filling commenced for many days and many nights. Side note for anyone doing repair on any glass boats or anything, just say no to polyester and vinyl resins, they aren't worth the time and money it takes to manufacture them. Only use quality epoxy resins and glass cloth.

So we jumped out and bought all the supplies, and contacted my nearly life long buddy Rick who is also a confirmed GlassAholic and along with me we fell off the wagon and started to get very excited at the prospect of laying a large amount of glass cloth and epoxy resin.![Razz [razz]](./images/smilies/msp_razz.gif)

![Razz [razz]](./images/smilies/msp_razz.gif)

![Woot [woot]](./images/smilies/msp_w00t.gif)

![Woot [woot]](./images/smilies/msp_w00t.gif) We got right to it, I'd just come off a graveyard shift and he met me at the house at 9:00am on a sunny day. We laid fourteen ounces of glass in two layer on the bottom in single sheets, yeah I know we're crazy but that's the way we roll!

We got right to it, I'd just come off a graveyard shift and he met me at the house at 9:00am on a sunny day. We laid fourteen ounces of glass in two layer on the bottom in single sheets, yeah I know we're crazy but that's the way we roll!

After Fourteen OZ of Glass and Gallon of Marine Water Proof Resin.

And a Final Top Coat of Resin to Fill the Weave.

After the glass we trimmed all the excess sanded the edges smooth and started to think. Off to chat with the experts on the Wooden Drift Boat Forum http://www.montana-riverboats.com/phorum/list.php?3. We know glass and epoxy is very impact resistant, all in all very strong stuff but it's weak point being abrasion resistant, it just can't take scratches and water together. Side note polyester or vinylester boats are not made with water proof material. Period, no argument accepted as it is what it is, it's why manufacturers put gel coat on the outside, it's marginally better when it hasn't been compromised. I will entertain discussion at a later date if needed.

Trimmed and Ready to Proceed.

Stay Tuned for Part 2.

On the way home from Tumwater, stopped Cabelas and the License store and transferred the title on the trailer.

At Home in the Drive.

We knew there was going to be some repair to the bottom as the glass had been broached in a couple location. We got her off the trailer and turned her over on to the saw horses....Note to self, when turning over a drift boat have as many people as possible. Sickbayer and I just about busted a nut on the flip but we made it. After we got her turned we looked at the little spots and found the glass had let go of the wood on the entire bottom. and we were able to pull it off in a couple of pieces. At this point we found the boat had been built with a double bottom, so it has two sheets of three eighths in the center danger zone with glass in between.

Bottom Ripped Off and Ready to Go.

And the sanding and filling commenced for many days and many nights. Side note for anyone doing repair on any glass boats or anything, just say no to polyester and vinyl resins, they aren't worth the time and money it takes to manufacture them. Only use quality epoxy resins and glass cloth.

So we jumped out and bought all the supplies, and contacted my nearly life long buddy Rick who is also a confirmed GlassAholic and along with me we fell off the wagon and started to get very excited at the prospect of laying a large amount of glass cloth and epoxy resin.

After Fourteen OZ of Glass and Gallon of Marine Water Proof Resin.

And a Final Top Coat of Resin to Fill the Weave.

After the glass we trimmed all the excess sanded the edges smooth and started to think. Off to chat with the experts on the Wooden Drift Boat Forum http://www.montana-riverboats.com/phorum/list.php?3. We know glass and epoxy is very impact resistant, all in all very strong stuff but it's weak point being abrasion resistant, it just can't take scratches and water together. Side note polyester or vinylester boats are not made with water proof material. Period, no argument accepted as it is what it is, it's why manufacturers put gel coat on the outside, it's marginally better when it hasn't been compromised. I will entertain discussion at a later date if needed.

Trimmed and Ready to Proceed.

Stay Tuned for Part 2.